Step By Step Dye Penetrant Testing Process

The dye penetrant technique for review is a nondestructive

test for materials open to the surface. It might be utilized on such materials

as aluminum, magnesium, metal, copper, cast iron, steel, tempered steel,

carbides, certain plastics, and earthenware production. The basics of the

strategy are infiltration of the imperfection by the Dye Penetrant - the expulsion

of the overabundance Penetrant from the surface - improvement of the sign -

investigation. A dark red sign will check the imperfection.

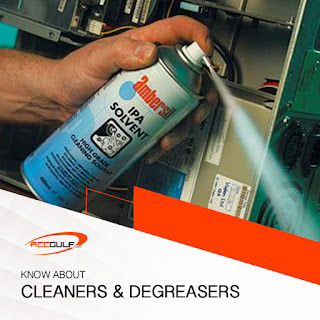

Surfaces ought to be liberated from outside materials and

paint. Oil, oils, and so forth. forestall infiltration and ought to be

expelled by pre-cleaning with a Cleaner/Remover or by dissolvable degreasing.

Scale, sand, earth, and so forth trap penetrant and impede evacuation, along with these lines wire brushing or comparative pre-cleaning is vital. Paint must be

expelled from zones to be tried. Here are the steps to conduct a dye penetrant

testing:

-

Pre-clean parts: This can extend from crushing

and wire brushing to simply cleaning the part with a cloth dampened with the

cleaner/remover. The surface should be liberated from rust, scale, paint, oil,

and oil, and be sufficiently smooth to clear off the penetrant without leaving

buildup.

-

Apply the penetrant: Next, the specialist

applies penetrant splash can to the surface which is in sharp red shading. The

specialist needs to hang tight for 5 to 15 minutes and rely upon test

methodology. Right now, penetrant fluid enters to the split (regularly isn't

unmistakable).

-

Remove the penetrant: At the point when adequate

entrance time has been permitted, clean the surface off with a spotless towel

or material. Try not to flush surface with Cleaner/Remover since this will

hinder affectability. Rehash this method with extra cleaning until the lingering

surface penetrant has been evacuated.

-

Apply the developer: A flimsy, light covering of

engineer ought to be splashed on the part being inspected. An abide time should

be seen to permit time for the color to leave the defects and make a sign

(blemish) in the engineer.

-

Evaluation stage: In this, you assess the test

outcome dependent on the acknowledgment criteria showed in the affirmed test

strategy. If you don't mind note one sign may be viewed as a flaw and be

dismissed by one acknowledgment criteria and be acknowledged by another. So it

is basic that the test is assessed with the right acknowledgment criteria.

-

The dye penetrant testing report: Lastly, the technician prepares a report and shares the test results with the customer.

In case you’re looking for dye penetrant testing in Dubai, check out products from ACC Gulf, they’re your

partners in all things reliable.

Thank you for sharing this blog !!

ReplyDeleteFind here the best double side film tape manufactures in UAE

Nice blog !!

ReplyDeleteFind here the best thermal insulation materials uae